Table Of Content

The beam quality will be reduced accordingly, which is acceptable for some applications. Second, the power-conversion efficiency will typically be somewhat increased. Third, the stability zones of the resonator (see below) will become wider—as a result, the laser can be operated over a substantial range of powers, even if thermal lensing is strong.

Precision Laser Engraving Services in Los Angeles, CA from Hai Tech Lasers

Hisense PX2-PRO TriChroma Laser Cinema - Review 2024 - PCMag Middle East

Hisense PX2-PRO TriChroma Laser Cinema - Review 2024.

Posted: Fri, 19 Apr 2024 07:00:00 GMT [source]

As if cake wasn’t delicious enough on its own, Etsy shop LoveGarlands’ laser cut black acrylic cake topper really makes us want to celebrate. It is lightweight but strong, among the strongest and most dimensionally stable plywoods. It has a great price point and is commonly used for making laser cut scale models, jewelry, model boats, model airplanes, product housings, drones, clocks, prototypes and signage. Etsy shop LettersToYou specializes in custom hand lettering and calligraphy, and these table numbers show that a computer isn’t required to create a beautiful script. These custom table signs are all hand drawn, laser cut in sturdy MDF wood and painted in gold, rose gold, silver, black or white to coordinate with a variety of wedding color schemes.

Fundamentals of semiconductor lasers

Our laboratory and production facilities have the latest laser-cutting machines, ensuring that your project is finished quickly with the highest quality. With over 40 years of experience in the laser-cutting industry, we have developed an efficient laser-cutting process to provide you with the highest quality products and services. Laserod provides a variety of laser cutting and micromachining services for clients in Los Angeles, California, and in all parts of the United States and in Canada. In the last module, we learned about how semiconductors can emit light. In this module, we will apply this knowledge to learn about the basics of light emitting diodes.

It all starts with a laser logo

If you’re inspired by all the laser cutter projects above, stop messing about. An optical switch traps the low-energy laser pulse in the main amplifier for four passes through the laser glass slabs. Mirrors at both ends of the glass amplifier cause the photons to travel back and forth through the glass, stimulating more electrons to drop to their lower energy states and emit photons. This process produces huge numbers of photons of the same wavelength and direction—an extremely bright and straight beam of light. In this way the initial low-energy pulse is amplified by more than a quadrillion times to create 192 highly energetic, tightly focused laser beams that converge in the center of the Target Chamber.

We specialize in designing and manufacturing custom-made and OEM lasers to suit our clients' particular needs. In fact, 75% of the lasers manufactured involve some type of custom work. Interestingly, even ultrashort pulses can exhibit a very high degree of temporal coherence, in that case involving coherence between subsequent pulses in a regular pulse train. This is related to the formation of a frequency comb as the optical spectrum.

KolAi Denim unveils AI-based certification for denim laser design - just-style.com

KolAi Denim unveils AI-based certification for denim laser design.

Posted: Wed, 13 Mar 2024 07:00:00 GMT [source]

I’ve chosen the Scandinavian Pine Cone as an example here, but that’s just one of many awesome designs you can cut and engrave for your home. Laser Templates has, as the name implies, a library of available templates and stencils for laser cutting and engraving. This heart, ribbon, and rose cut is an easy mesh that you just need to add LEDs too to make a lovely lamp that stands out well as either a main light source or just a light-up decoration. It also shows how any laser cut mesh, if put on a stand, can act as a charming LED lamp. This portable chess set, courtesy of Instructables, is perfect for chess players on the go.

The first is that the output is naturally fiber-delivered, which makes it easy to couple into many laser machine tools and to integrate the laser with robotic delivery systems. A single set of pumps and gain fiber can typically produce output powers of up to multiple kilowatts, but it is also possible to use fiber combiners to enable power scaling, achieving output powers exceeding 10 kW. Finally, fiber lasers have high wallplug efficiency (the conversion of input electrical energy into laser light) compared to CO2 and solid-state lasers, and can also have low maintenance requirements. The light from the pump laser diodes passes through a pump combiner which is spliced into the “active” fiber to excite the active element in the fiber core.

In NIF, as in most large lasers, intense flashes of white light from giant flashlamps “pump” electrons in large slabs of laser glass to a higher-energy state that lasts only about one-millionth of a second. A small pulse of laser light “tuned” to the excited electrons’ energy is directed through the glass slabs. This laser pulse stimulates the electrons to drop to their lower, or ground, energy states and emit a laser photon of exactly the same wavelength. As laser cutting projects, they’re useful, versatile, and can be made to look like just about anything. The one above is a great example of the kind of coffee pod holder you can make with a laser cutter, you just have to make sure the actual holders are the right size for the kinds of pods your using. For something a little simpler but no less special, laser cutting wooden lamps is an excellent way to turn some leftover wood into a beautiful addition to any home.

More specifically, one usually means laser oscillators, but sometimes also includes devices with laser amplifiers, called master oscillator power amplifier (MOPA). To complete the process of light creation in a fiber laser, the spool of fiber is bound by fiber Bragg gratings at each end. They are essentially mirrors that create a high power resonator when they are placed at both ends of the doped fiber. The longer wavelength light (the 1064nm output) resonates between these gratings. The gratings reflect light at an angle determined by the geometry of the reflecting surface. As the light is bounced back and forth between the two gratings, it is being amplified with every pass.

Often, a laser medium can accumulate some amount of energy over some “pumping” time in order to then release it within a much shorter time. A laser can not operate if the gain is smaller than the resonator losses; the device is then below the so-called laser threshold and only emits some weak luminescence light. Significant power output is achieved only for pump powers above the laser threshold, where the gain can reach (or temporarily exceed) the level of the resonator losses. In laser technology, a wide range of optical components such as laser crystals, laser mirrors, polarizers, Faraday isolators and tunable optical filters are used; see the article on laser optics.

NIF, like the ruby laser, emits pulses of light lasting only billionths of a second. NIF beams start out as invisible infrared light and then pass through special optics that convert them to visible green light and then to invisible, high-energy ultraviolet light for optimum interaction with the target. A mirror on one side of the laser’s optical material bounces the photon back toward the electrons. The space between mirrors, or the “cavity,” is designed so the photon desired for the particular type of optical gain medium are fed back into the medium to stimulate the emission of an almost exact clone of that photon. They both move in the same direction and speed, to bounce off another mirror on the other side to repeat the cloning process. In a laser beam, the light waves are “coherent,” meaning the beam of photons is moving in the same direction at the same wavelength.

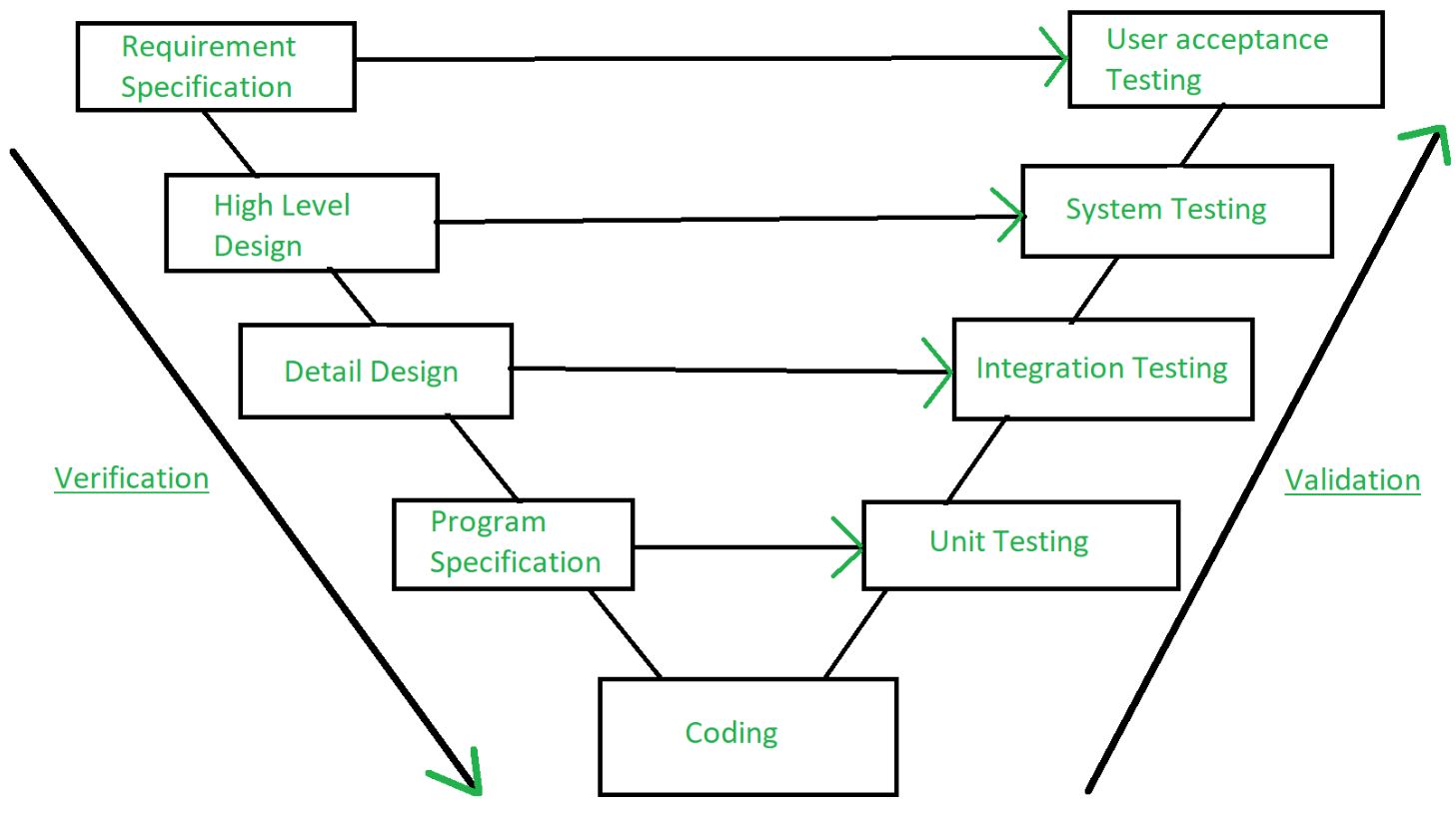

All our lasers are manufactured in a clean room environment, by skilled staff and with the highest of quality. In industrial development, it is common to derive some product design from an older design, rather than starting from scratch. Although this may appear to be very economical, there are significant risks, particularly in cases where the first design has not be properly worked out and documented in a process as described above. A central challenge is that modifying some detail of a laser design may easily have unexpected side effects, introducing new problems which then require additional measures, which again can have side effects.

Well known ethnic patterns blend the traditional with the modern, and the combination of the wood base with matte black and gold details creates memorable statement pieces. Since many makers specialize in making with certain materials, we have grouped the design ideas into subsections by materials to make your browsing experience easy. So you’ll see all the wood jewelry, acrylic jewelry and so forth together. Speaking of woodland creatures, this stately stag from Etsy seller KreativDesignCo has a contemporary Scandinavian style illustrated by a combination of geometric shapes. Matte black acrylic gives it a modern and sleek look, but you can warm it up by choosing the wood option. Made from 6mm thick walnut (shown) or oak veneered board, Etsy seller Jessica6Designs hand finishes and treats each laser cut design to withstand spills and drips.